Deep Learning Neural Networks develop logical reasoning capabilities by self programming. Eliminates need for additional processes.

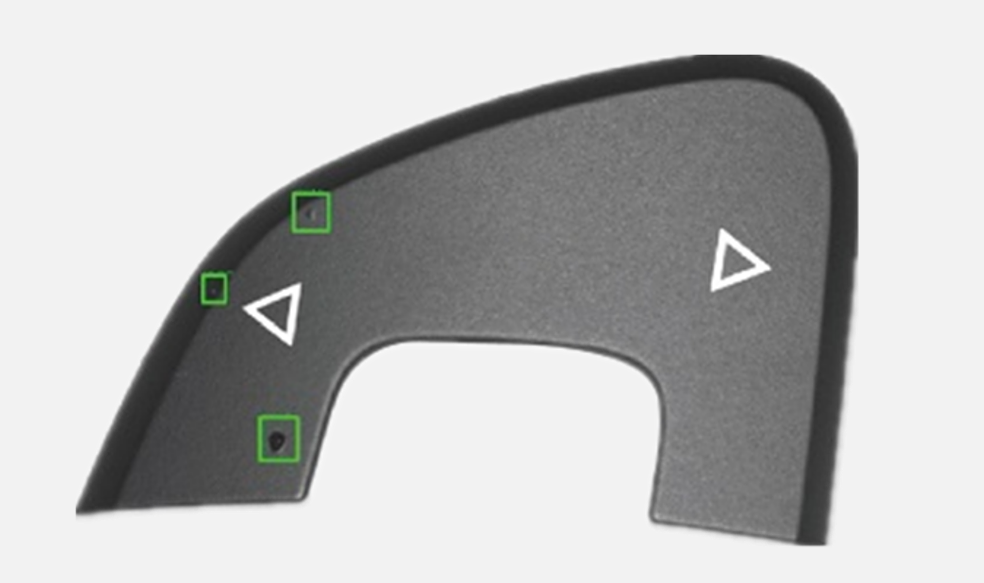

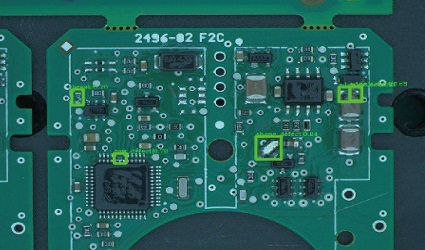

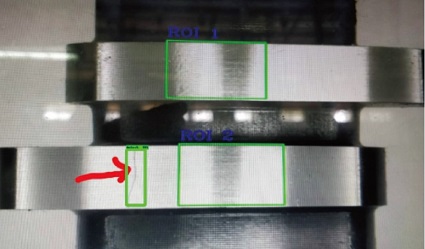

Complete reliability in fault detection, through consistency not possible in traditional systems. Amplifies confidence in product quality and life cycle.

Variations in products are constantly added to reference/library without human intervention.

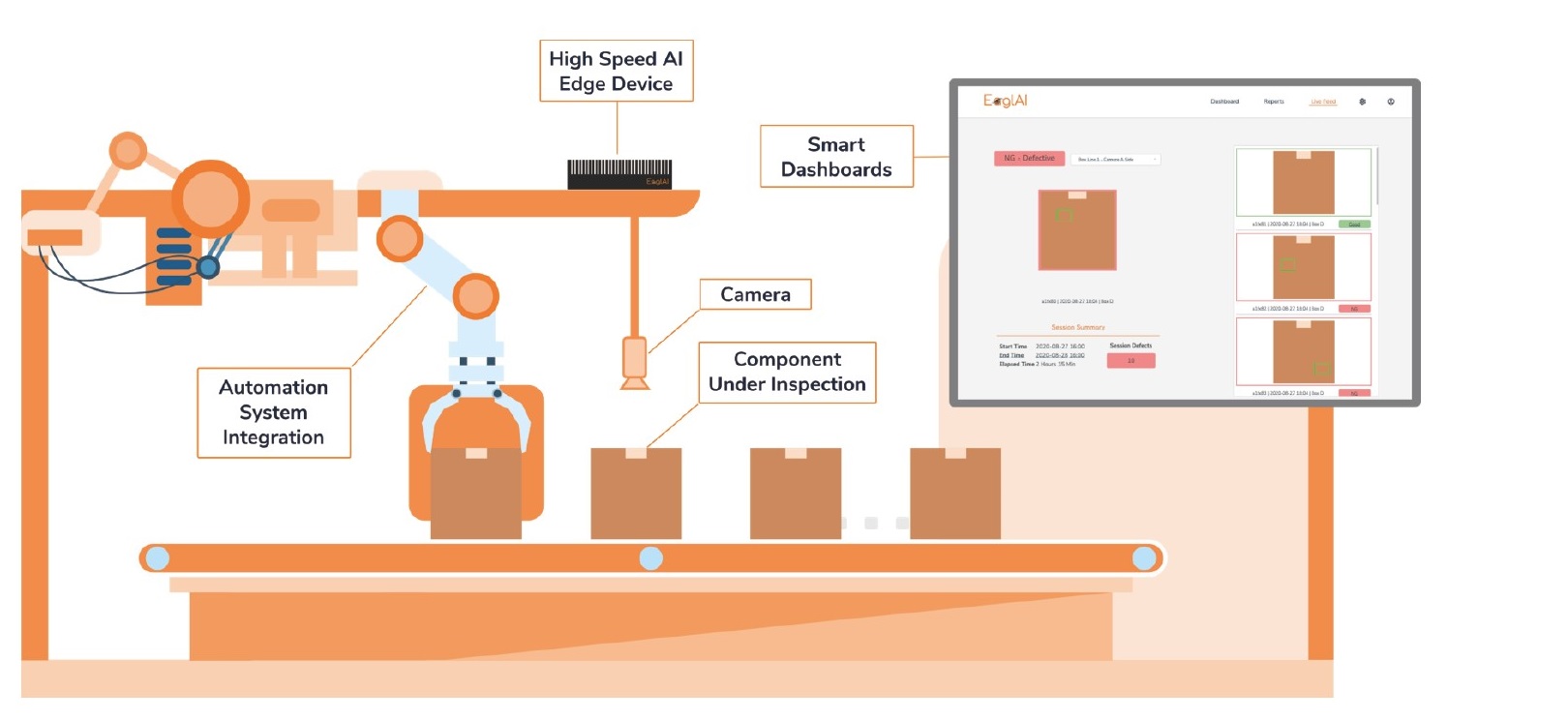

Eliminate tradeoffs in quality control in high speed environments with real-time, consistent quality control and complete accuracy even at 20+ FPS (frames per second).